Air, rail, road and sea are moving more freight than ever before. US Atlantic and Gulf ports saw a record number of containers passing in 2022. With so much freight on the move, intermodal container monitoring is critical for accessing the right information and monitoring precious shipments across lengthy journeys.

Why is monitoring intermodal containers so important?

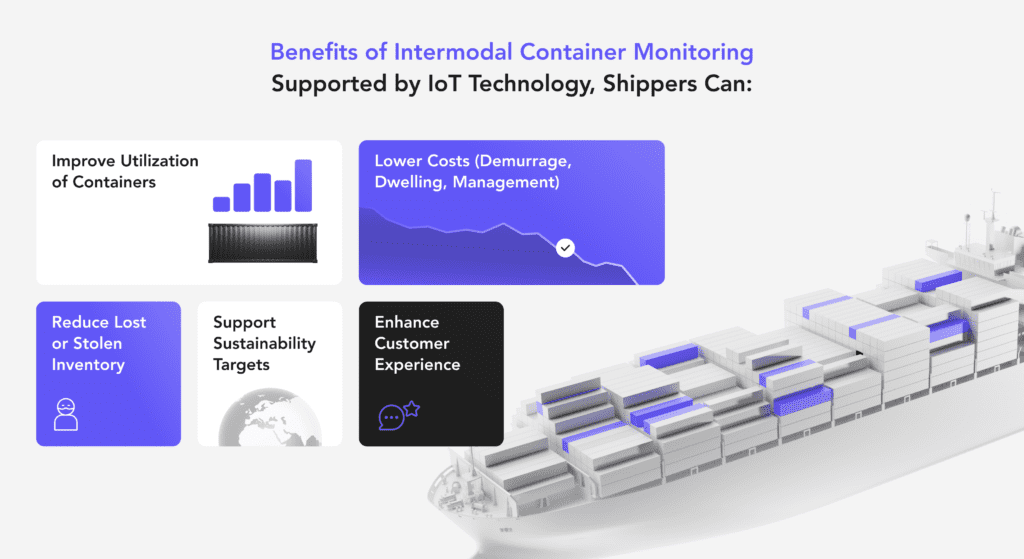

IoT monitoring technology provides valuable data to increase and optimize container use, reduce transportation-related costs and improve supply chain sustainability. Optimizing container use and sustainability, in particular, go hand-in-hand with intermodal monitoring technologies ensuring that fewer containers are moved, either half full or empty.

Additionally, several NGOs raised the issue of container loss on land or at sea, including a distinct lack of data on how and why containers are getting lost and who’s responsible for retrieving them.

Intermodal tracking systems help reduce container loss and the environmental implications that come with it while supporting business owners to recover valuable shipping containers quickly.

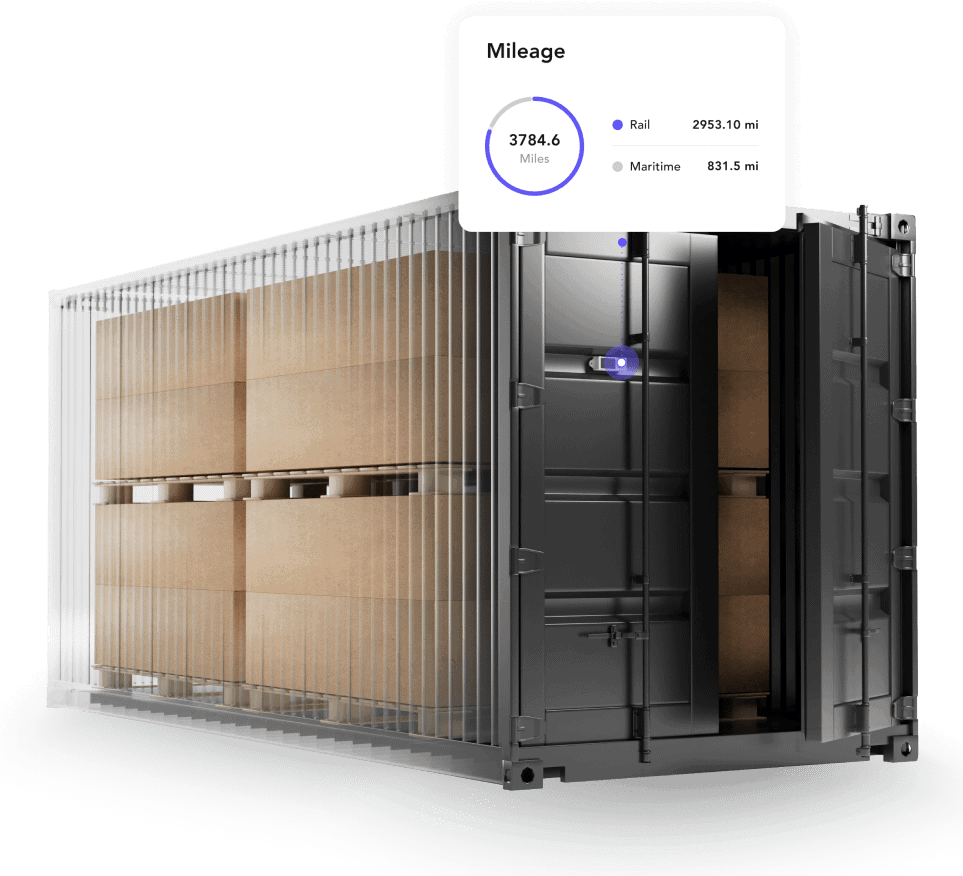

Monitoring intermodal containers provides visibility across the entire shipping route. This is vital, especially if containers move from ship to rail and rail to road. With multiple transitions, if problems arise, it is possible to pinpoint exactly where, when, and why they happened, thanks to real-time data tracking.

What are the benefits of intermodal container monitoring?

Data is the currency of modern intermodal shipping. While Asset Intelligence and Big Data are here, in what ways do they serve businesses in container monitoring?

The possibilities of container monitoring to optimize container movements are exciting. Key benefits include:

Fully actionable insights

One of the most significant benefits of a monitoring system for intermodal containers is access to actionable insights. With intermodal monitoring, it is possible to monitor the exact location of a container, establish geo-location boundaries, and set alerts and notifications.

This enables more informed decision-making about inventory management while identifying supply chain issues like bottlenecks or inefficiencies. Better visibility means making informed and strategic decisions to improve efficiency and reduce costs.

Total supply chain visibility

Not only is it possible to track the location of intermodal containers, but there is also visibility over supply chain functions. Shippers are better equipped to plan shipping routes, bypass delays, and seamlessly track shipments.

Sensors can compliment an intermodal monitoring system, adding the ability to monitor the following:

- Temperature

- Humidity

- Shock

- Door opening

- Live location

Operational efficiency

An intermodal monitoring solution allows tracking container movements from a single, centralized system. This means data is accessed in one place at any time. This information streamlines operations to ensure containers are used in the most efficient way possible.

In addition, a container monitoring system provides access to data on container utilization rates – helping identify ways to reduce costs and improve asset use.

Time-saving

Intermodal container monitoring saves time in multiple ways, including:

- Better communication – when a single system tracks shipping data, it ensures communication is aligned across an organization. Additionally, reporting can turn data points into actionable insights that can be communicated cross functionally and accurately.

- Better planning – the ability to track the exact container location at any point along the shipment journey improves planning. For example, knowing that a container is at the correct port is only half the story. Has it made it to the correct loading bay? Has it been loaded on the right ship, train or truck? Knowing these data points in real-time saves significant time and resources in re-planning or re-routing containers.

- Minimized delays – a cargo tracking system sends notifications and alerts when containers arrive at their destination. Shippers can quickly identify potential problems and take corrective action by tracking containers. This helps to avoid delays and disruptions.

Improve customer experience

Intermodal shipment monitoring and real-time data improves the customer experience through:

- Increased visibility – the added visibility and shipment status provided by a container tracking solution can be passed on to the customer for proper planning and assurance.

- Improved communication – real-time container tracking enables the sharing of timely updates with customers. Customers can be alerted by specific events or delays to take action quickly.

What companies are currently implementing intermodal container monitoring?

Container monitoring is growing as technology improves and companies learn of the benefits of digitalizing their assets.

Hapag Lloyd has partnered with Nexxiot to digitalize a significant share of the three-mio TEU fleet, enabling the worldwide monitoring of shipping containers for the first time. With the adoption of innovative IoT technology and analytics, Hapag Lloyd became the first carrier in the world with the ability to provide customers with real-time data about every container movement.

Spectainer, a provider of foldable containers, partnered with Nexxiot to enable real-time visibility of their fleet of COLLAPSECON containers.

With their containers upgraded to include Nexxiot’s latest Asset Intelligence technology, the fleet is now easily monitored from origin to destination.

With a digitalized fleet, shippers and shipping lines can automate specific handling processes to optimize operations, increase cargo safety, enhance the customer shipping experience, and improve sustainability.

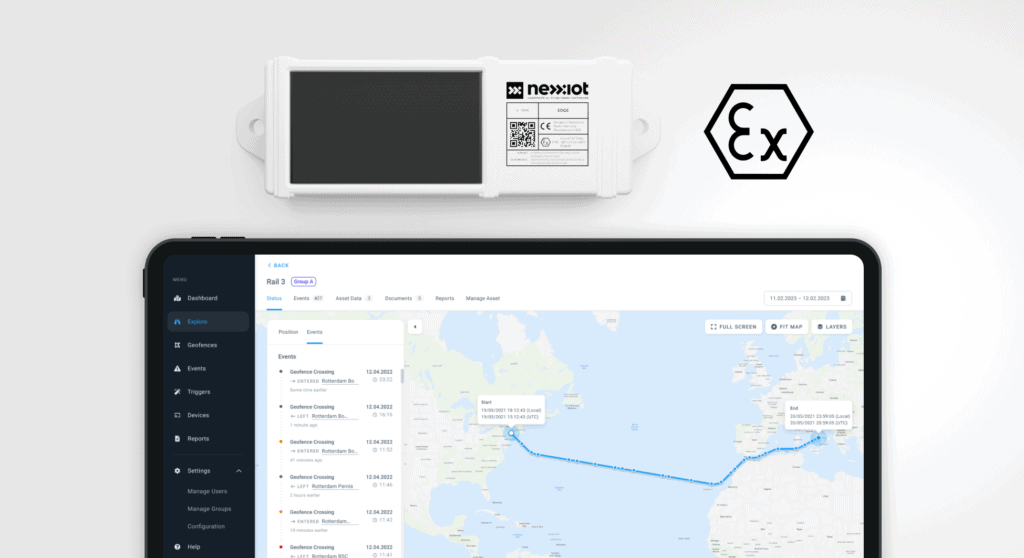

Monitoring intermodal containers with Nexxiot

Nexxiot’s ecosystem of Edge gateway and Connect Intelligent Cloud make it possible to track intermodal containers across the end-to-end shipment journey. Our ATEX-certified solution provides visibility with the strictest safety standards for any cargo type, including simple consumer products, dangerous goods, and any transport mode, including rail and ocean freight.

Edge enables real-time monitoring to help ensure the safety and security of containers and the valuable cargo inside. Sensors can also accompany the gateway to expand the collected data, including temperature, humidity, shock and more.

Outside of hardware, Connect Intelligent Cloud provides the point of access for prime data and clear insights to keep track of containers all-in-one place. This not only adds convenience and never before seen visibility into container status and location, but it empowers shipping companies to improve nearly every facet of their business while becoming more agile and resilient. Discover how your business and customers can benefit from embracing digitalization and intermodal container monitoring.