What is Supply Chain Visibility?

Supply chains have gotten significantly more complex over the years while maintaining their incredible importance to both singular businesses and the global economy. Any shakeup in supply chain processes may have a strong ripple effect on many other stakeholders, as was evident during the COVID-19 pandemic.

Luckily, the industry has developed to the point where numerous solutions aid supply chain visibility, which can be defined as monitoring, tracking, and reacting to any events during deliveries or cargo movement. Devices can adhere to containers that provide data, ranging from GPS coordinates to shock alerts and CO2 levels.

Numerous benefits can be extracted from supply chain visibility (SCV), meaning that businesses are looking for ways to take advantage of the newest technologies to optimize logistics further.

Why is supply chain visibility so important?

Maintaining supply chain visibility is essential for any business shipping to multiple destinations. Without software and devices, understanding weak points, managing failed deliveries, claiming insurance, and optimizing routes would be significantly more complicated.

It is unlikely that supply chain operations will get any simpler in the future. Historical trends indicate that businesses want to expand and deliver more goods to various locations. As such, supply chain visibility is already important and will become increasingly vital over the coming years.

Companies like Nexxiot are heavily investing in solutions that would ease the management of supply chain operations through next-generation devices that can last numerous years without any manual charging and transmit tons of business-critical data. These devices are becoming the preferred way to implement supply chain visibility.

Coupled with next-generation devices, supply chain visibility software is usually implemented. Such software usually works through web or mobile applications that provide a dashboard, which collects, aggregates, and presents data from the aforementioned devices in an easy-to-understand fashion.

These supply chain visibility solutions enable businesses to track and manage their logistics much more effectively and to collect data that can be analyzed for further operational efficiency. For example, shipping container or railcar information about load status, temperature or door open/close status is accessed in the dashboard, which may be used to reveal safety concerns, inefficiencies and optimization opportunities.

Finally, governments are also beginning to realize the importance of supply chain visibility. The European Union has announced a directive to improve supply chain visibility within logistics that will soon become mandatory for all businesses involved in the industry.

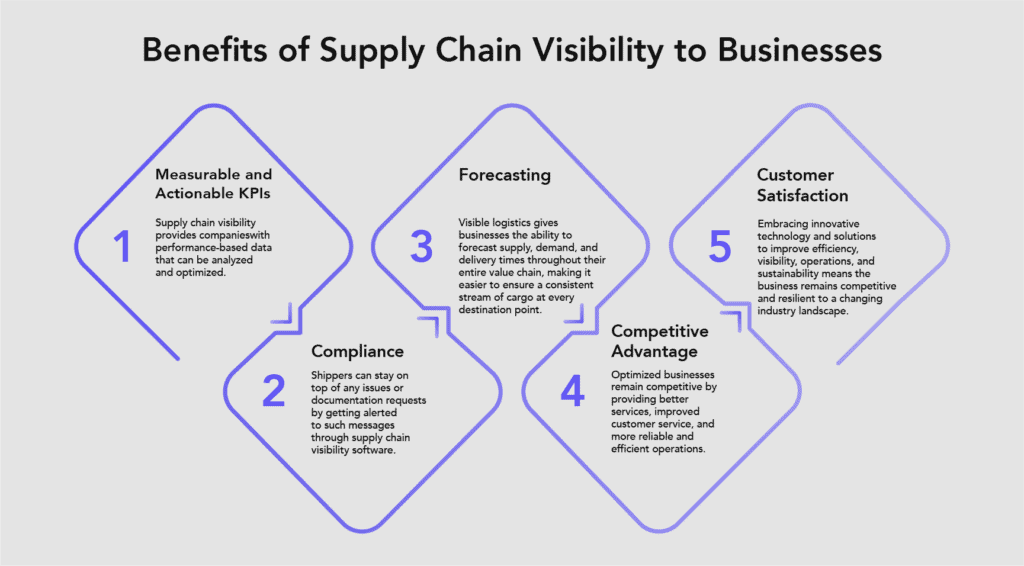

Benefits of supply chain visibility

Supply chain visibility provides many benefits, most of which stem from two key areas: data and monitoring. Real-time cargo monitoring can help businesses stay alert and reactive whenever something goes awry during deliveries or cargo movement.

Additionally, real-time alerts and constant cargo visibility make it easier to make a case for insurance claims if some unfortunate event cannot be resolved otherwise. It’s relatively easy to prove accidents or mishandling when real-time information has been transmitted to a dashboard.

While monitoring provides primarily protective benefits, helping businesses get out of sticky situations, data is what makes supply chain visibility solutions truly shine. They can provide businesses with the following:

- Measurable and actionable KPIs. Supply chain visibility provides companies with performance-based data that can be analyzed and optimized. Many managers use a Key Performance Indicator (KPI) system that attempts to improve the most important revenue-driving aspects of the business.

- Compliance. End-to-end visibility gives business owners insight into how carriers and institutions process goods. Shippers can stay on top of any issues or documentation requests by getting alerted to such messages through supply chain visibility software.

- Forecasting. Visible logistics allows businesses to forecast supply, demand, and delivery times throughout their entire value chain, making it easier to ensure a consistent stream of cargo at every destination point.

- Customer satisfaction. Optimized businesses provide better services. Customer satisfaction is, then, equally raised simply by ensuring that the logistics are in place and the end-user of the supply chain can always get the required product or service.

- Competitive advantage. Embracing innovative technology and solutions to improve efficiency, visibility, operations, and sustainability means the business remains competitive and resilient to a changing industry landscape.

While supply chain visibility can bring tremendous benefits to any company, they do not come by default. As mentioned, a significant part of the benefits is extracted through thorough and detailed data analysis. So, all of the data transmitted by next-generation devices will be much less useful if a business doesn’t have the people that can take advantage of the information.

Improving supply chain visibility

Supply chain visibility is relatively easy to implement. Current generation solutions combine devices and software into one package, meaning businesses don’t have to look to several suppliers to create an advanced tech stack.

Additionally, having a supplier supporting technological interoperability will prevent running into information sillos. With an interoperable approach, the software and IoT devices communicate perfectly within multiple suppliers’ ecosystems, removing unnecessary data access steps.

As such, it’s best to find a supply chain visibility provider that has open APis or follows ITTS2 protocol. With such a provider, all that is left to do is mount devices on containers or railcars and start harnessing the benefits of supply chain visibility.

Frequently asked questions:

What is real-time supply chain visibility?

Real-time supply chain visibility uses software and devices to get information on every step of the supply chain, from raw material processing to final product delivery. Each step is carefully recorded, with all important data transmitted to a company database, making understanding every event within the supply chain easier.

What is inventory visibility in a supply chain?

Inventory visibility refers to a company’s ability to understand how much, where, and the status of their goods throughout the supply chain. Inventory visibility data may include the total load (or number) of goods, the number of them in delivery and processing, and the amount of them ready for the end user. Information on overall visible supply chain fulfillment may also be included.