Introduction

Technology is transforming the transportation industry to support the needs of supply chain stakeholders. Innovative products are delivering unprecedented asset intelligence and are reshaping the intermodal sector for the better. New insights and services are driving significant improvement by bringing together the Internet of Things (IoT) and AI analytics.

Intermodal transportation involves shipping goods in a container using different modes of transport like ship, rail and road to move the box. The challenges of moving goods huge distances through different modes means visibility is essential. Multiple stakeholders require the actual status of assets and cargo as they seek to optimize processes, deliver quality services and manage risks along the route.

Asset intelligence delivered by integrated hardware, software and analytics means carriers and cargo owners have continuous transparency. With reliable insights, users can optimize asset utilization, improve safety and security and provide assurances of compliance throughout the intermodal journey.

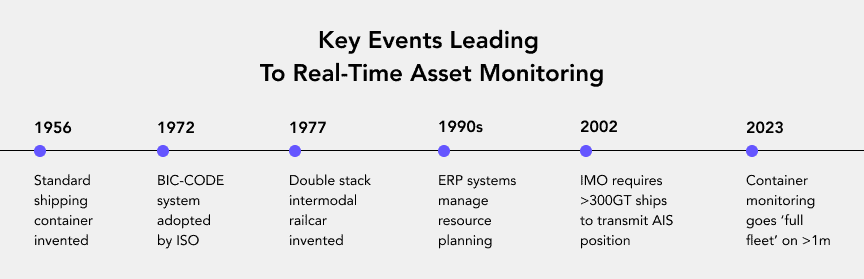

In 1956, Malcolm McLean invented the standard shipping container.1 The intermodal system of transporting cargo drastically reduces the time it takes to load and unload vessels. It also made it significantly safer and more secure.2 Shipping containers revolutionized the way goods are moved around the world and how ships are packed and unloaded. Now, 70 years on, active hardware devices are revolutionizing how shipments are monitored in transit.

This white paper describes what smart containers are, how they work and how they improve ocean carrier operations. We look at a use case of a company leading the way and the industry’s future with these capabilities now driving growth.

The Age of Smart Containers

What are smart containers?

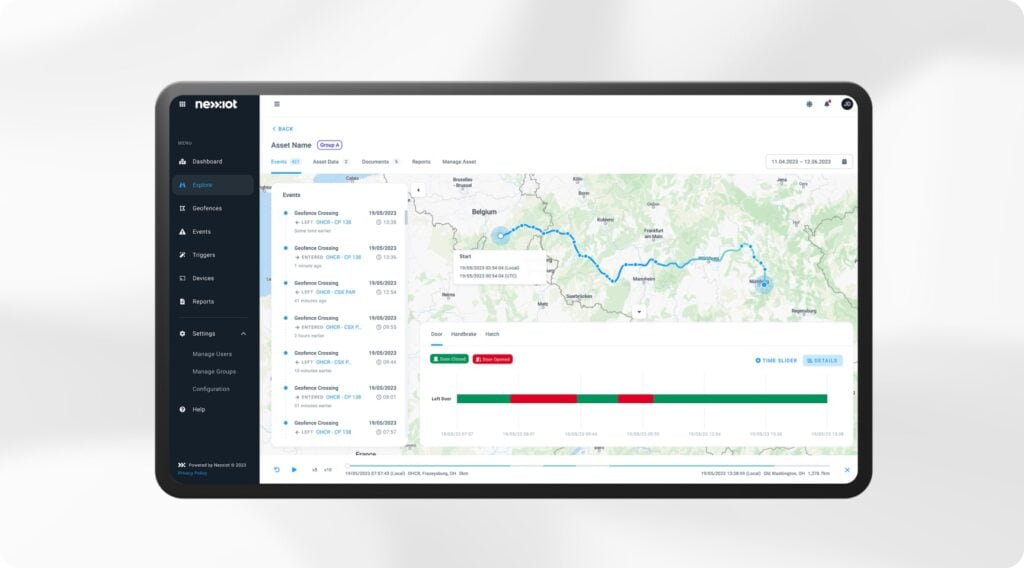

Smart containers are standard shipping containers equipped with IoT technology.3 The sensors transmit real-time data on the container’s location and cargo temperature, humidity, and other important parameters. This data is sent to a secure platform that creates value using machine learning algorithms to detect important events and manage processes.

How do smart containers work?

Smart containers are created by installing self-powered IoT gateway devices onto existing intermodal shipping containers. These gateways gather and relay information on both the container’s status and the conditions of the cargo it holds. These devices use multiple communication protocols to transmit data from the container to a cloud-based platform so this data can be processed and insights accessed from anywhere. Multiple sensors can also be installed onto a single container to address additional use cases. Stakeholders access asset data through web-based applications, enabling them to monitor the container’s status and automate processes with updates as they happen.

Why are smart containers important?

Smart container data brings efficiency and security to intermodal transportation. With real-time monitoring capabilities, ocean carriers and cargo owners can improve routes, prevent delays, avoid losses and reduce the risk of theft, damage or accidents.

How has container tracking evolved, and where are we headed with smart containers?

Moving containers relies upon processes involving Container Numbers, Bill of Lading, Booking Numbers, Automatic Identification Systems, and vessel AIS positions. Supply chain participants have long looked to technology to provide a level of visibility. One example is in rail, where RFID technology previously enhanced asset location monitoring. In 1991, the American Association of Railroads made RFID devices, also known as AEI tags, a standard, and they were deployed at specific places on USA rail tracks to confirm an asset’s location at a single point in the journey.4

The maritime industry is challenging, with more assets, routes, complexity and data silos from multiple participants. With the invention of energy-efficient IoT sensors and data collection and sharing, the industry has shifted into detailed condition monitoring and accurate real-time locations for all modalities, including maritime, rail and road.

Drewry’s 2022/2023 report estimates that the number of smart containers will expand eightfold over the next five years. This shift has grabbed the attention of shippers and ushered in a new era of data-driven services.

Real-Time Visibility to Improve

Supply Chain Sustainability

Cargo transportation makes up 8% of global greenhouse gas emissions. Growing economies are expected to triple the global demand for freight by 2050.5 Nearly all freight transportation runs on oil and gas. If we continue business as usual, freight will become the highest emitting sector by 2050. Inefficient processes and a lack of data and governance result in business uncertainty, poor cargo quality and costly mitigation when things go wrong.

The global supply chain is central to human survival. Transportation of cargo ensures access to the resources we all need daily. Lack of supply chain oversight and limited process control threatens this mechanism. Conversely, supply chain transparency and real-time asset monitoring have the potential to significantly improve safety, sustainability and efficiency across global logistics.

Improving Carrier Operations

with Smart Containers

Real-time asset intelligence enables carriers to transform their strategies, enhance service levels and make performance gains.

Smart containers provide the exact location of the cargo and offer a comprehensive view of a container’s journey. With this level of transparency, carriers are better equipped to manage their container fleet deployments and deliver improved customer service.

The next part of this paper explores three key areas where smart containers are making a significant impact on carrier operations:

- Optimizing Asset Utilization and Reducing Costs

- Managing Compliance and Reducing Illegal Transport and Theft

- Delivering Better Customer Experience and Process Control

Each of these dimensions is reshaping the future of intermodal transportation.

Optimizing Asset Utilization and Reducing Costs

With unpredictable operating expenses and global trade uncertainty, carriers search for strategies to improve asset utilization and control costs – no matter what unexpected circumstances emerge.

Smart containers ‘unlock’ new services by transforming a container into an ‘agent’ in its own processes. Optimizing utilization includes steering container movements, reducing idle time, and speeding up handling operations.

1. Increasing the Number of Trips per Container

Optimizing container usage means increasing the number of trips each container makes to maximize the asset owner’s revenues.

This can be achieved by:

- Optimizing routes, equipment management and the positioning of empty assets.6

- Facilitating seamless transfers across different modes of transportation.

- Minimizing idle time and maximizing the duration containers are in motion.7

When a container is due to arrive at a depot, real-time data enables the carrier to coordinate the next assignment for that container with confidence. This minimizes the idle time at the depot – resulting in improved container utilization and more revenue for the carrier.

2. Reducing Detention and Demurrage Costs

Detention and demurrage fees are charged when containers are stored in a terminal or port. These fees are a major concern for ocean carriers. Digital solutions make it possible for carriers to reduce dwell time and make continuous planning improvements whilst maintaining high standards in customer service.

Reduce detention and demurrage costs by boosting visibility:

- Improve customs clearance by pre-clearing cargo in advance of the container arriving at the port/terminal.

- Secure additional ‘free days’ when data shows there are potential issues which might delay the container.

- Facilitate cargo dispatch as far in advance as possible to ensure the loading or unloading party is ready to act.

Through real-time updates, carriers can manage their container fleet flow more efficiently, reducing idling time, which translates to better cost control.

3. Reducing Deadstock

In an industry where efficiency and speed are paramount, deadstock containers standing around unused are a significant drain on resources. Advanced tracking and predictive analytics of smart containers help minimize the impact.

Smart container fleets create millions of data points. By analysing the high-resolution historical data of cargo movements, carriers can more accurately anticipate and match supply with demand. This reduces the costs of underutilization and allows carriers to simultaneously increase service levels. Smart containers reduce deadstock, optimize carrier operations, and improve the bottom line.

Managing Compliance and Reducing

Illegal Transport and Theft

Smart containers improve security and provide the data for compliance within global logistics. With sensor technology and real-time tracking, carriers can detect and prevent the transport of illicit goods and theft and create more trust for stakeholders.

Smart containers simplify compliance with better digital processes and legally valid oversight – removing the risk of regulatory violations and associated costs.

Enhancing Container Security

Maritime transport can be exploited for illicit trade by transnational organized crime, including cargo theft, drugs trafficking, wildlife smuggling, and human trafficking.8

Smart containers detect irregular activities like unauthorized container access, movements or unusual cargo conditions. Specific sensors detect illicit cargo, like wildlife or human trafficking. In this case, increased levels of carbon dioxide provide an immediate alert which can be sent to logistics operators or customs officials for prompt action, saving lives.9

Real-time tracking allows carriers to monitor unplanned or unauthorized container movements. Any deviations from expected routes, approved corridors or schedules trigger swift investigations to reduce the risk of illicit goods trafficking. By enhancing asset intelligence and response, smart containers make the global trade environment safer and more reliable.

Regulatory Compliance

The ability to record, transmit, and process data simplifies compliance reporting and contributes to a safer supply chain. Equipped carriers demonstrate compliance with the International Maritime Organization’s (IMO) regulations as follows:

- Structural Safety Compliance (CSC Convention): The CSC convention includes two Annexes pertaining to the testing, inspection, approval and maintenance of containers and to the structural safety requirements and tests of containers, respectively. Real-time monitoring helps to ensure that containers are kept in optimal conditions, reducing the risk of damage and accidents.10

- International Convention for the Safety of Life at Sea (SOLAS): SOLAS covers requirements for stowage and securing of cargo or cargo units. Should an issue arise, tracking capabilities provide valuable data to identify what occurred and when, and alert parties to solve an issue before it becomes more serious.

- The International Maritime Dangerous Goods (IMDG) Code: The code sets out detailed requirements for maritime transport of dangerous goods. For containers carrying dangerous goods, specific temperature or humidity ranges may need to be maintained. The continuous monitoring provided by smart containers helps ensure these parameters stay within required limits, aiding compliance with the IMDG Code.

In addition to IMO regulations, smart containers can help streamline customs clearance processes and prove adherence to complex customs regulations. Smart containers provide a multifaceted approach to regulatory compliance, enabling carriers to meet international shipping laws and directives for greater accuracy, efficiency, and safety.

Delivering Better Customer

Experience and Process Control

The adoption of IoT-enabled AI is changing the way the shipping industry provides customer experience. By harnessing the capabilities of live reporting and dashboard ideation, carriers deliver transparency to the customer and offer new services with locations, routes, cargo quality and security.

1. Improving Transparency

Customers can monitor the location and physical condition of goods during transit. With improved visibility, customers understand whether cargo is in optimal condition and if the journey is proceeding as planned. Insights mean cargo owners make proactive adjustments to minimize the risk of damage or delay and optimise the value they get from the goods.

Asset transparency does more than keep the customer informed. It fosters deeper trust in carrier services. Customers, reassured by real-time information, view digital carriers as value-adding partners. By enhancing customer experience, carriers create stronger, long-term shipper-carrier relationships.

2. Fast Resolution of Issues

Monitoring assets is essential to resolving issues. Should problems occur, carriers can now swiftly respond.

Whether a delay, a bottleneck, a deviation, or a problem with the cargo, hard data and facts are in hand so carriers can ensure service quality, provide updates and offer alternatives to meet clients’ business objectives. AI human-computer interfaces offer an easy, intuitive way, with natural conversational language, to rapidly create reports, charts, maps and strategies for new business models and products.

3. Value-Added Services

The massive data generated by a large fleet of IoT devices is harnessed to offer value-added services that go beyond traditional carrier services.

Equipped carriers provide customers with in-depth insights into shipment histories and patterns. Reports can include data on cargo quality, safety, security and emissions. With actionable insights, customers can optimize supply chain operations to make them more resilient.

Value-added services allow carriers to differentiate themselves. In a competitive market, digitalization is now a prerequisite to increase shipment value. Carriers can build stronger relationships with customers and open up new revenue streams to a broader array of stakeholders, including 3PL/4PLs, Customs, Ports, Financial Service facilitators and others. Smart containers are revolutionizing the logistics space as carriers increasingly deploy and leverage the data for more business cases.

4. Protecting Cargo Integrity

Smart containers protect cargo integrity. Sensors deployed with cargo allow shippers to continuously monitor environmental conditions like temperature, humidity, and shocks. Condition monitoring is crucial for shipments of pharmaceuticals, foods, perishable goods, and electronics, which all require specific conditions for safe transport and value retention.

Alerts and interventions ensure cargo quality. This protects the investments of cargo owners and the interests of other stakeholders like insurers or finance partners.vc

Digitalization

and Real-Time Monitoring Use Case

Carriers using smart containers are shaping the future of intermodal transportation. The question is, who will deliver the most innovation through their client offerings – via the deployment of big data and automation?

Born from Necessity

Supply chains constantly evolve, shaped by economic forces, trade policies, environmental pressures, and user demand. To navigate this, companies must be agile, adaptive, and well-informed. As we will see in these real-time monitoring use cases, digitalization enables companies to react quickly to changes, make fact-based decisions, and implement strategies for continuous improvement.

Hapag-Lloyd

Delivering even better value to its customers

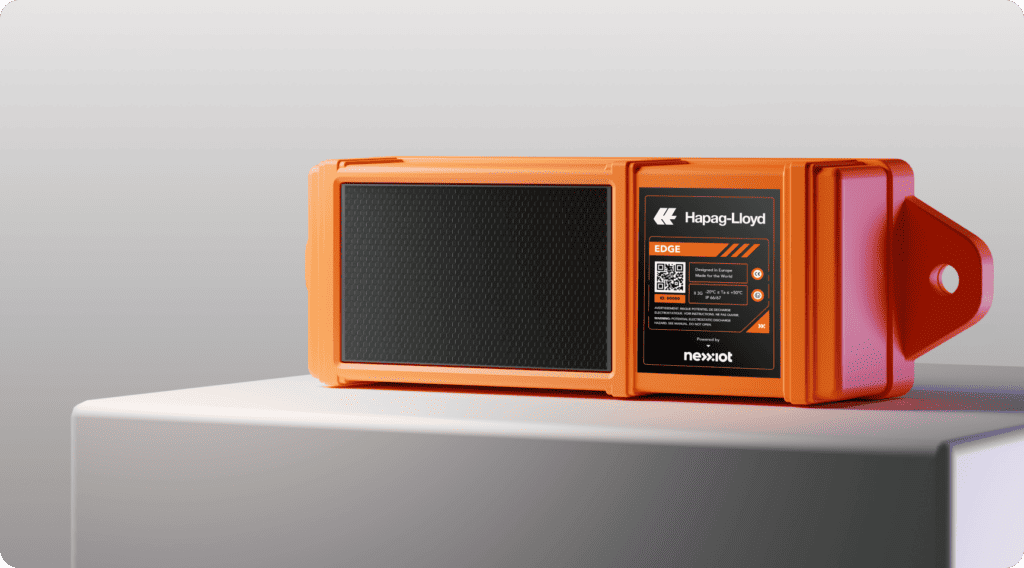

Hapag-Lloyd is the first major global ocean carrier to monitor in real time the location, movement, and status of all its standard containers. After introducing live monitoring for its reefer container fleet with Hapag-Lloyd Live in 2019, Hapag-Lloyd is installing innovative Edge gateways on all three million TEU standard intermodal containers.

Hapag-Lloyd’s strategic commitment to digitalization delivers unique value to its customers, who benefit from reduced risks, more accountability and greater confidence. Edge gateways transmit location-based data, measure temperature, and monitor movements, shocks and impacts. Hapag-Lloyd is offering new services and can also expand capabilities by adding further specific sensors to the asset.

Dr. Maximilian Rothkopf, COO of Hapag-Lloyd, says:

We are the first carrier in the industry to undertake such a far-reaching step towards the digitalization of container shipping. The containers leaving our depots with a tracking device will now be fully visible to us and our customers as well – whether they are in a terminal or moving on a truck, train, or barge.

Hapag-Lloyd’s Director of Container Applications, Olaf Habert, communicates a clear vision to build the world’s smartest container fleet and provide new high-value information to customers exactly when they need it. Hapag-Lloyd’s decision positions them as market leaders in real-time transparency and trust.

The Future of Smart Containers

According to its 2023 report, Drewry predicts by 2027, almost one-third of all containers will be equipped with telematics hardware.11

As businesses increasingly recognize the value of smart containers, their use is expected to expand. We can also anticipate more sophisticated usage of the data generated by smart containers. With advances in AI, companies will use this data to automate processes and decision-making. New Human Machine Interfaces (HMIs) are emerging where it becomes easy to create ad-hoc reports, insights, and strategies, analyse trends, and implement new business models to capture value from data iteratively and immediately.

Four conditions are important to consider:

- Standards for safe device deployment

- Value for stakeholders

- Interoperability guarantees

- Safeguards for data security

Benefit from Generative Al

Artificial Intelligence (AI) is expanding the usability of supply chain data and revolutionizing the way decisions are made through the shipment journey. LLB generative AI offers users the chance to take on different roles, ask questions in new ways and interrogate both old and new data for new insights and all kinds of outputs in text, charts, reports and other media.

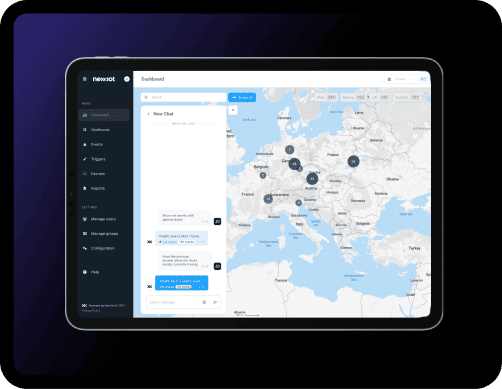

Systems like Scope AI are designed to reduce the number of steps and skill sets required to access the most impactful data and to empower stakeholders to make better choices more quickly.

Make Strategic Decisions in Seconds

Clients who use Scope AI are able to analyze their business on a deeper level. Now, it’s easier to generate reports and make key decisions in minutes, not days.

- Theft and Shock Detection

- CO2 Reduction Strategies

- Utilization Management

- Demurrage Cost Reduction

- Journey Optimization

Get to Know Scope Al,

Edge and Globehopper

SOFTWARE AND DATA

Scope Al

AI assistant that enables access to real-time IoT data through a conversation.

- Accessed through Connect Intelligent Cloud

- Ask questions with voice or text

- Receive insights as maps, charts and tables

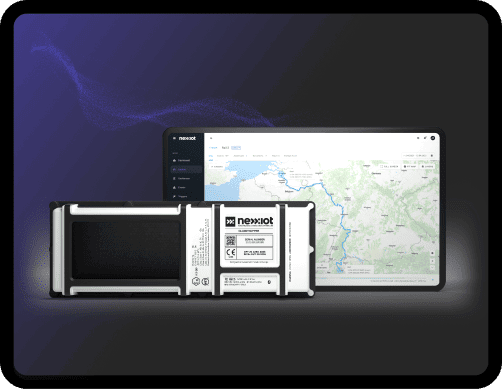

GATEWAYS (ASSET-LEVEL)

Edge

The sensor gateway for non-powered cargo assets for every transport modality.

- Real-time location with data updates every 60 minutes when moving

- Safety certification: ATEX Zero maintenance for 8+ years

- Firmware updates: over-the-air

- Sensor connectivity: BLE 5.1

GATEWAYS (ASSET-LEVEL)

Globehopper

A new standard in railcar and tank container hardware.

- Location and shock detection, with data updates every 5 minutes

- Safety certifications: ATEX, IECEx and Hazloc Zero maintenance for 8+ years

- Firmware updates: over-the-air

- Sensor connectivity: BLE 5.1, ITTS Interface 2 and IEEE 802.15.4

About Nexxiot

Nexxiot provides real-time Asset Intelligence for shipping containers and railcars through its highly reliable hardware, software and analytics. The technology automatically detects location, shocks, movements, modalities, border crossings, and more. These capabilities enable users to monitor the condition of their assets, automate business processes, and provide new services to stakeholders.

Nexxiot has one of the largest device fleets installed globally, with more than one million assets equipped for clients, including Hapag-Lloyd, Knorr-Bremse, VTG, Ermewa, Deutsche Bahn, SBB, Railpulse members, and others.

Headquartered in Zurich, Switzerland, Nexxiot has more than 150 engineers and industry experts, serving clients from its offices in Germany, Sweden, and North America.

Nexxiot’s mission is to remove uncertainty in the global supply chain,

empowering clients to achieve their growth and sustainability goals.

About the Authors

Erik Lund

Executive Vice President, Maritime & Logistics, Nexxiot

With an extensive background from transport and logistics, combined with valuable experience in LogTech and maritime innovation, Erik leads Nexxiot’s maritime and logistics solutions business to help accelerate the adoption of real-time asset intelligence technology within shipping and logistics to achieve real insight and value for easier, safer cleaner global transportation.

Bjorn Jacobsen

Chief Product Officer, Nexxiot

With vast experience from logistics to container shipping and asset management, Bjorn is focused on supporting clients in creating business value by driving new operational and commercial use cases across the full range of logistics assets.