In January 2019, a tragedy occurred on the Great Belt Bridge in Denmark when a semi-trailer became detached from a pocket wagon and collided with a passenger train during a storm. This sadly resulted in the loss of multiple lives. Leading rail companies decided to make major investments to stop accidents like this from happening again. The question is, how can this efficient transport be maximized without increasing the risk of accidents? Until now there has been no technology to provide alerts to inform workers about the locking status of hitch and kingpin when a semi-trailer is loaded on the pocket wagon. With the arrival of Nexxiot’s Kingpin Monitor all that has changed.

Making the transportation of cargo more sustainable is a topic of great importance. The best transportation strategies combine different modes of transport for each part of the trip. Roads are important and are chosen mostly because the network is dense, and they reach nearly all factories, warehouses, depots, and retail outlets. Moving goods by rail is more efficient than the road as it produces between four to seven times less carbon emissions per tonne of goods moved. The common-sense solution is to use rail for the long distances and road for the first and last mile. To do this, the handling of transfers between road and rail must be streamlined and improved.

Transporting goods by rail is extremely safe, yet risks remain

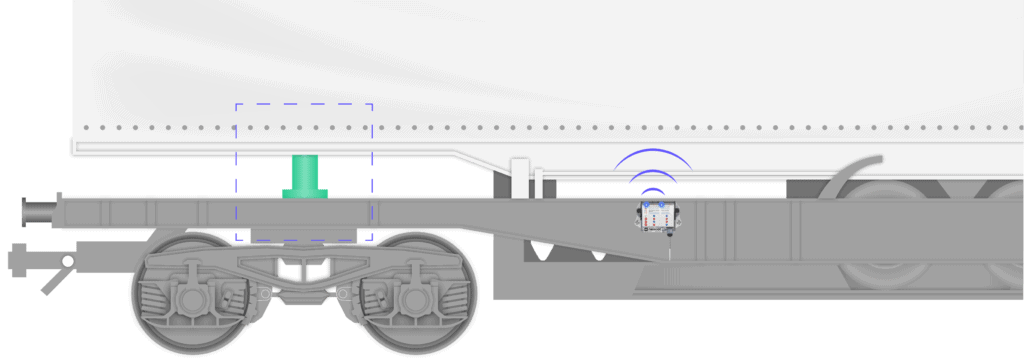

On the quest for speed and efficiency, new challenges arise that need to be solved with new technology. The semi-trailer has a kingpin which must be locked in place to secure it properly to the pocket wagon via a hitch. This is a tricky procedure especially when the crane operator is working high above the rail tracks and operating the manual controls in all types of incremental weather. It often takes multiple workers a long time to ensure safe loading, and errors can be catastrophic.

Designing sensors to work with heavy industrial equipment is tough

Pocket wagons operate in a heavy load and high-stress environment. This is far from ideal for delicate electronic instruments like sensors. Any viable solution must be sensitive enough to deliver useful information across a broad spectrum of operating conditions yet be robust enough to survive in a harsh environment where frequent impacts occur.

With over 200K sensor gateways already deployed, Nexxiot is familiar with the need to design robust hardware solutions for optimising supply chain assets like railcars. In 2019 Nexxiot started developing the Kingpin Monitor in close collaboration with its client VTG. The objective was to develop a reliable maintenance-free sensor to instantly indicate the kingpin lock status. Nexxiot engineers worked closely with workers in the field to define the parameters and prototyping began.

Today the Kingpin Monitor is being deployed to speed the process of loading semi-trailers onto pocket wagons and ensure the locking mechanism is properly engaged. As part of Nexxiot’s sensor hardware suite, it communicates with the Nexxiot Connect Intelligent Cloud via the Globehopper gateway. When speaking to terminal operators, it became clear that people working with loading equipment also needed better visibility on the locking system. Now crane operators are equipped with a digital assistant – Kingpin Monitor Remote Control. This means they receive accurate real-time indications on status of kingpin and hitch for better safety and efficiency. This reduces the possibility of human error. Nexxiot’s Kingpin Monitor Remote Control is not intended to replace human operators, but rather assist them to improve efficiency and prevent possible catastrophic accidents.

Conclusion

As a driver of the digital logistics of tomorrow Nexxiot’s goal is to enable a five percent reduction in global cargo carbon dioxide emissions by increasing cargo transport efficiency and eliminating waste caused by empty runs and inefficient routes. The ambition is also to create better tools for workers to improve workplace conditions, operating processes and safety. Safety doesn’t have to mean incurring cost. It can be a driver for better business, which means reduced risks, better processes, lower insurance premiums, and fewer accidents as well.

The supply chain has come under considerable focus in the past few years. Logistics is essential to create wealth and prosperity, but it’s also a source of risk and insecurity. The transport of goods and raw materials requires networks to function well. As we seek to optimize, speed is often increased to the detriment of safety. To make the most of our transport assets, networks and resources, the best cargo transport options must be made available at each stage of the journey.