Out of all goods carried by trains, LNG movement by rail is the most controversial. So much so, in fact, that the USA has suspended their final decision on whether to allow LNG transportation by rail until June 30th, 2024 or until a rule is agreed upon, whichever is earlier.

There are valid arguments to both sides of the fence. On one hand, liquified natural gas is an essential part of the economy, powering enormous amounts of aspects of businesses, transportation methods, and even livelihood essentials such as heating. On the other hand, a single derailment, such as had happened in Ohio, can cause enormous harm to the environment and people.

Even as the world continues to iron out existing regulations and create new ones, transporting LNG by rail remains an extremely attractive shipping option. Many of the other methods, such as maritime vessels or pipelines, have similar issues with some unique benefits. LNG by rail is no different – there are some drawbacks, but also major advantages.

What is LNG and how is it transported?

LNG is an acronym for liquefied natural gas, which is predominantly a form of methane, refrigerated, liquid with some ethane in the mix. Cooling down methane to a liquid state has numerous benefits, but the largest one is that it takes up significantly less space, reducing it to 1/600th of the volume it would be in a gaseous state.

Refrigeration, in the context of transporting LNG, is far removed from something you’d encounter in daily life. To turn methane from its gaseous state to a liquid state, temperatures of or below -162° C (-250° F) are required. Any interaction (such as during a spill or leak) with regular air or room temperature will quickly turn the liquid back into its gaseous state.

Regardless of the method chosen, whether transporting LNG by rail, barge, or pipeline, it is delivered to a regasification terminal where the liquid can be turned into a gaseous state safely. Natural gas is then distributed through pipelines or other transportation methods to the final destination where it’s used for energy, heating, or other purposes.

Risks of transporting LNG

While, intuitively, many might think that the primary danger of transporting LNG is a potential explosion caused by methane, these are extremely unlikely, at least in the technical sense of the term. Liquefied natural gas does not burn at all, only its vapors do. Methane, however, is extremely flammable, ignites and burns quickly, causing risks at plants. Vessels transporting LNG are usually relatively safe as the leaks will be rather small, causing rapidly igniting fires without explosions.

Yet, methane brings its own unique risks. First, it’s colorless and odorless (albeit, when transported for use, another gas is added to give it the distinctive smell as a safety measure), making it hard to detect whenever a leak happens. Outside of the previously mentioned ignition risk, methane is also one of the most powerful greenhouse gasses, which, even when resolved quickly, can negatively impact the environment.

Finally, due to methane’s properties, large quantities of the gas can cause an asphyxiation hazard to anyone exposed, including both humans and animals. Combine such a nasty quality with the gas being odorless and colorless and the entire encounter can become quite confusing and dangerous.

How is LNG transported by rail

Due to the many concerns and risks associated with LNG shipping, rail transport for these types of goods usually has numerous strict rules and existing regulations. As mentioned previously, some countries have even outright banned rail transport for LNG, preferring pipelines or barges to make deliveries.

There are, however, many reasons to choose rail transport for LNG. It’s a relatively safe shipping method overall with extremely large capacities and decent speeds. In general, rail transport stands somewhere in the middle of everything when accounting for safety, sustainability, speed, cost efficiency, and numerous other factors.

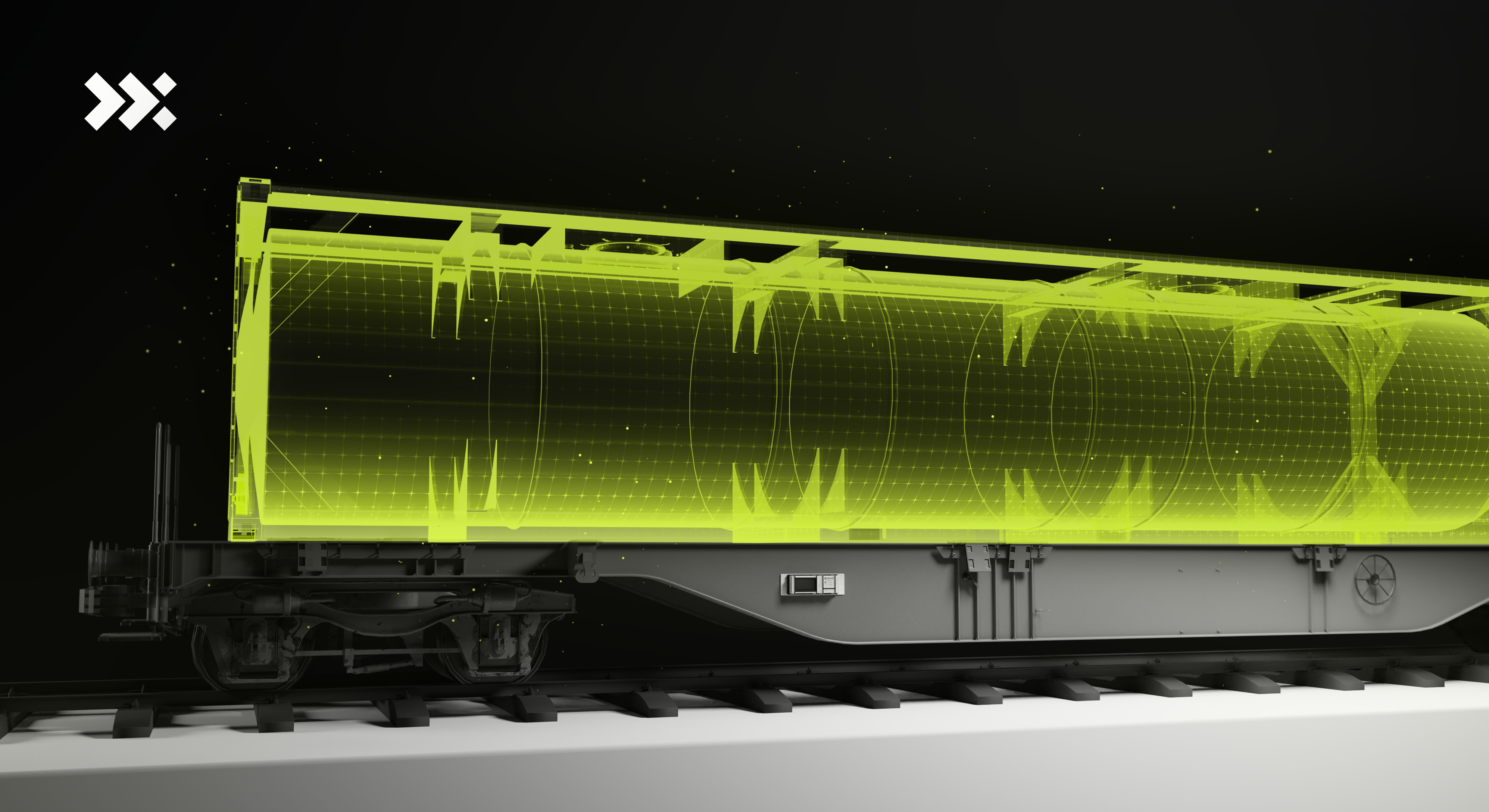

Transporting LNG by rail requires dedicated tank cars. A rail tank car made for transporting LNG will have several specific features:

- Several layers of material to match enhanced outer tank requirements for safety.

- Telematics or asset intelligence devices to monitor tank pressure.

- Thermal insulation and temperature maintenance capabilities.

- A dedicated crash buffer to absorb any potential shocks.

- Anything else that’s required for existing regulations for transporting hazardous materials.

Due to the existing regulations and ongoing discussions around transporting LNG by rail, such a rail tank car design isn’t commonly seen. While some versions are available, it’s definitely not the most popular and most used rail tank car design.

A long chain of these dedicated rail tank cars are filled up with LNG to prepare for transportation. Due to the risks of transporting LNG by rail, routes may need to be reassessed for safety as derailments can cause major issues.

Other than the requirements, the LNG by rail transportation follows the same rules as with all delivery methods. A train would arrive at a dedicated regasification terminal where the stored LNG can be converted into a gaseous form and then delivered to the final destination.

Conclusion

LNG transportation by rail, while hotly debated, follows much of the same rules as with all other methods. The main concerns arise due to the inherent risks of LNG transportation rather than anything to do with rail. While accidents and derailments can be truly horrible, the damages caused by pipeline leaks or other adverse events can be of similar degree.

Additionally, as the discussion towards rail transport for LNG continues, it’s likely that existing regulations will be enhanced to continually improve safety of the process. Rail transport has the potential to become a major part of the overall LNG transportation supply chain across the globe as long as regulators arrive at agreeable conclusions towards the process.