When it comes to safety, rail transport has earned its distinction as the safest method for transporting goods over land.

According to the Association of American Railroads (AAR), “more than 99.9% of all hazmat moved by rail reaches its destination without a release caused by a train accident.” Railroads have approximately 1/10th of the total hazmat accidents trucks have, and the accident rate for rail has continuously decreased since 2000.

Rail’s high safety standard stems from a blend of regulations, technology, training, and a controlled operating environment, all working together to minimize risks and enhance security. These conditions have advanced to drive a safer and more secure rail network.

In the 21st Century, the advancements within rail freight transportation have encompassed a range of innovations and regulatory initiatives, including:

- Positive Train Control (PTC): PTC systems monitor and automatically adjust train operations to comply with safety rules, preventing accidents caused by human error, speed violations, and unauthorized track incursions.

- Rail Safety Improvement Act (2008): Provided a framework for various safety improvements in the freight rail industry, including mandates for PTC implementation, hours-of-service regulations, and enhanced inspection requirements.

- Adoption of Safer Railcar Designs: New railcar designs have improved the safety of transporting hazardous materials, like the DOT-117 tank car, which includes enhanced features to prevent material leakage in the event of an accident.

- Technological Innovations in Inspections: Railroads have made progress in testing drones, ultrasound, and other advanced technologies to inspect tracks and equipment, enabling more frequent and precise monitoring and early detection of flaws, contributing to a reduction in derailments and other accidents.

Room for Improvement in Rail Safety

Rail has seen considerable progress in becoming the safe and reliable form of cargo transportation it is today. That said, there is more work to be done to improve rail safety and further reduce the number and severity of rail accidents.

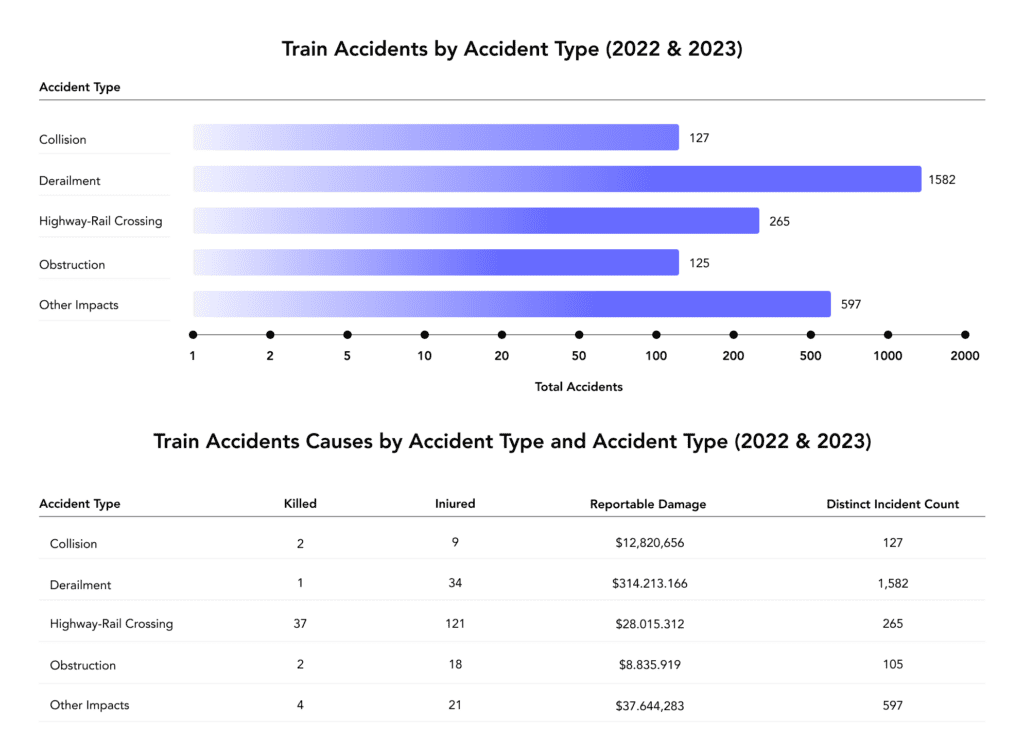

According to the Federal Railroad Administration (FRA), there were over 1000 reportable train derailments across the US last year. From January to June 2023, there have been nearly 400 reported cases.

The February 3rd derailment in East Palestine, Ohio, because of its hazardous nature and its significant impact on the community and environment, was one such case that brought national attention to the topic of rail safety and raised the question: what can be done to improve the future of rail safety?

How Digitalization is Improving Rail Safety

An article published by the Global Railway Review states: “Ask a railway operator what the number one reason for digitalization in rail is, and the reply will be, ‘to ensure safety.’”

Digitalization and IoT technology are critical in supporting a safer future for rail. Sensors connected at the individual railcar level support real-time condition monitoring and preventative maintenance before conditions deteriorate and cause incidents.

These digital solutions create an interconnected ecosystem of gateways, sensors, and cloud-based digital infrastructure. This network empowers rail shippers, car builders, railroad owners, and shippers by providing them with actionable data and insights, facilitating more proactive, informed, and strategic decision-making. The ecosystem’s advanced capabilities include setting triggers and alerts and defining geofences, leading to heightened efficiency and precision in asset management.

As digital adoption increases in rail freight transportation, more data will be collected, and more opportunities for improved safety will be recognized and implemented. When shippers have complete visibility over assets, processes and long-term decision-making are improved, and operations are safer.

Three ways digitalization is increasing rail safety

- Improving Visibility

Monitoring devices capture key data, which is accessible via a cloud-based interface, to give operators a complete view of what’s happening with railcars in real time.

With railcar monitoring solutions, location, delivery status, impact events, cargo and railcar conditions can be monitored and accessed in one platform.

For example, one can look at the improved visibility of railcar braking systems, which helps operators to improve safety and protect critical rail assets. The data gathered helps prevent unexpected outages, reduces maintenance costs, and indicates wear and tear early.

Conversely, limited data makes it risky to optimize maintenance without compromising safety. Access to highly accurate mileage data for every asset and data gathered from brakes and other subsystems make the decision-making process easier and more effective.

- Reducing Human Error

The Federal Railroad Administration (FRA) lists human error as one of the major causes of train accidents. This broad category encompasses mistakes ranging from miscommunication, signal violations, and failure to inspect or maintain equipment properly to non-compliance with safety regulations. Such errors can have a detrimental impact on rail safety.

Equipped with real-time tracking and intelligent data analytics, railcar operators and staff can have greater accountability and visibility over railcars’ status and even the cargo’s condition inside. These technological solutions allow for continuous monitoring, early detection of potential problems, and immediate alerts. If issues arise, the precise data and insights generated by these systems are invaluable in pinpointing the cause or extent of the impact.

By enhancing the awareness and responsiveness of rail personnel, these innovations are playing a crucial role in minimizing human error and further bolstering rail safety.

- Ensuring the Safety of Hazardous Cargo

The transportation of hazardous goods continues to rise in the US, reflecting a growing reliance on rail for moving chemicals, fuels, and other hazardous materials. According to the AAR, freight trains moved more than 2.2 million carloads of chemicals in 2021 and 2.3 million in 2022.

Implementing advanced railcar monitoring systems enables operators to closely track conditions and events related to hazardous cargo. With immediate insights into temperature changes, humidity and shock levels, rail operators can act proactively to ensure the safety of these sensitive goods.

For example, immediate warnings can be issued in response to concerning changes in conditions, allowing preventative measures to be taken before accidents occur. Furthermore, these systems are designed to facilitate rapid response in the event of an accident, with alerts and triggers that help operators quickly direct emergency services to contain and manage harmful or hazardous cargo. Modern technology is helping to maintain the integrity of hazardous cargo and enhance overall rail safety.

Nexxiot is Driving Digitalization in Rail

Rail freight stakeholders are demanding visibility and accountability. Nexxiot’s solutions, with IoT hardware – Globehopper gateway, sensors and software – help rail operators to complete the digitalization of entire railcar fleets improving visibility, safety and efficiency. The technology is also accessible to shippers, who, by request, can equip their railcars with gateways and sensors to meet their individual needs.

The Globehopper gateway is a zero-maintenance solution designed explicitly with rail safety in mind. It has all safety certificates, extensive capabilities to connect with multiple sensors and tracks assets for a lifetime of more than ten years.

Get in touch with us and see how you can benefit from real-time visibility in rail: